Basically, there are three main types of capsule-filling machines: Tamping pin, semi-automatic, and Doctor. These three types are all designed to help you fill capsules in the most convenient way possible.

Dosator type

Unlike the tamping pin capsule filling machine, the dosator-type capsule filling machine uses a different working principle. These machines are more reliable and improve efficiency. The doctor capsule filler is designed to fill powders and pellets for applications such as clinical trials. It also has a vacuum system to reduce solids.

Capsules are cylindrical containers that come in a variety of shapes. Some are round and oval. Others are tubs. The shapes can range from #0 to #5. When a capsule is closed, it is filled with powder. This process ensures that the product is uniform. However, there are several problems that can arise during the filling process.

Firstly, the machine requires support equipment to prepare the material for the capsule-filling process. Capsules are placed on trays, which are then aligned. After the capsules are filled, they are ejected through a discharge chute. They are then collected and packaged for distribution. The capsule-filling machine is used to ensure a seamless encapsulation process.

When the doctor’s capsule filling machine is in use, the operator can fill different types of powders. They should ensure that the machine is in perfect working condition. This involves cleaning the machine at regular intervals. It also involves replacing worn-out parts. The machine should be cooled before cleaning. It should be cleaned at least once every 500 hours of operation.

Doctor capsule filling machines are designed to work with a wide variety of powders and pellets. They have vacuum systems that pull capsule bodies loose. This allows the machine to easily handle hard gelatin capsules. It also allows the operator to fill suspensions and liquids. This machine can be used for various applications such as mass production, clinical trials, and micro-dosing powder applications.

In the process of doctor capsule filling, the machine forces powder into a cavity inside the doctor. The size of the cavity is dependent on the level of the plunger. This also determines the amount of powder that the machine can hold. The machine also has an ejection device that ejects the filling material into the capsule.

The doctor’s machine uses a piston-tamping method to fill capsules. The doctor has two pairs of doctor tooling systems. The first pair of doctor tooling systems pick up the powder and move it to the capsules. The second pair of doctor tooling systems then picks up the filling material and moves it to the capsule. The process is repeated for each hole.

When the capsule-filling process is complete, the machine removes the empty capsules from the capsule body and recycles them. Alternatively, the machine can remove failed capsules. The machine can also recycle unopened capsules. It is important that the capsules are locked after closing. The machine also has an emergency switch.

The machine has a graphics display, which makes it easy to operate. In addition, the doctor capsule filler is designed to work with capsules that are of a variety of sizes. It is important to know the various parameters of the machine and how to maintain it to ensure a reliable and efficient capsule-filling process.

Tamping pin

Using the tamping pin for capsule-filling machines is a common way to compress powder or pellet particles into capsules. This method has several stages that ensure the material is firmly compressed to the desired depth. If the tamping pin is not working properly, the process can lead to a mess.

When tamping pin capsule-filling machines are used, it is imperative to constantly monitor the process to ensure that the machine is working properly. There are different types of tamping pin machines on the market, and the correct one for your application depends on the size of the capsules you are filling. Using the correct tamping pin for capsule-filling equipment can prevent costly mishaps, and can ensure you get a product you can be proud of.

Tamping pin capsule-filling machines are designed with a dosing disc. This disc has six sets of precisely bored holes that enable the machine to deliver powder to a specified depth. When the dosing disc is rotated, it indexes the holes beneath five sets of spring-loaded tamping pins. The tamping pins press material to the desired depth, which can be as low as 0.3 mm.

Another type of capsule-filling machine is the Doctor type. This machine uses a more simple working principle but has several advantages over the tamping pin capsule-filling machine. The Doctor type is used for mass production, such as clinical trials, and can fill powders, pellets, or hard-gel capsules. It has a high level of accuracy, and the stress it places on the material can be modified for different applications.

These machines are designed to meet the hygiene requirements of the pharmaceutical industry. They are also durable and low-maintenance. This type of capsule-filling machine is not as operator-dependent as the semi-automatic model. These machines are a great choice for filling powders in pharmaceutical industries.

The next step is to fill the capsules with the material of your choice. This can be powder, pellets, or granules. After the capsules are filled, the capsules are sealed. The sealing process can be a challenge, however, as the powder is often sticky or hygroscopic. The best way to avoid this problem is to remove the excess powder from the capsules before sealing them. Then, place the capsules on a tray to prevent powder spillage.

The third type of capsule-filling machine is the soft-gel capsule filler. This machine is designed to produce soft-gel capsules. Soft-gel capsule filling machines can range from laboratory-scale to commercial-grade soft-gel machines. This type of capsule-filling machine can be used for filling soft gels, powder, and pellets.

If you are unsure about the different types of capsule-filling machines, you can compare the different features to determine which one will be best suited for your needs. When comparing the different types, you should also consider your application’s utility and environmental requirements. Besides these considerations, you should also be aware of the power and safety requirements. Some machines come with emergency stops, which can prevent the machine from running if power is interrupted. You should also look for a machine with a user specification guide. This will help you to get familiar with the different machine parts.

-

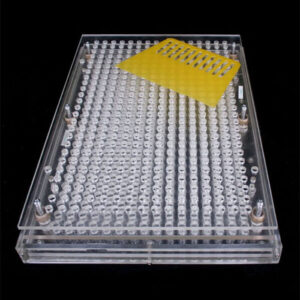

600 Holes Plexiglass Capsule Filling Machine$439.00

-

400 Holes Capsule Filling Machine Size 00$175.00

-

100 Holes Capsule Filling MachineFrom $35.99

Semi-automatic

Depending on a number of factors, a capsule-filling machine can produce a wide variety of products. However, the quality and efficiency of the process largely depend on the type of capsules it will be processing. The machine must be able to meet specific requirements, including material and size requirements. It may also be modified to suit different needs.

Capsules are made from several materials, including gelatin, HPMC (hydroxypropyl methylcellulose), soft gelatin, and protein. These products are used in a wide variety of industries, including food and pharmaceuticals. They are easy to store and inexpensive. They can be used in small quantities, making them an ideal option for small-scale pharmaceutical units. The process also reduces contamination.

A capsule-filling machine is a great way to keep your production running smoothly. It can be used with other equipment, including packaging devices, inspection, labeling, and counting. A quality machine will not only meet production demands but will also help your business save money on maintenance and operation costs.

A capsule-filling machine can be purchased from several manufacturers. The machine has a simple design, which makes it easy to operate and clean. In addition, it can fill a variety of capsule sizes, which makes it useful for both small and medium-sized pharmaceutical units. It can also be customized to suit the needs of your business.

The best capsule-filling machine is the one that can meet your production needs and provide you with the quality product you need. For this reason, it is important to find out the specific functions needed to make your production run smoothly. For example, the best machine may be one that is capable of producing a capsule that is small enough to fit in your bottle, but large enough to give you the micro-dosing you are after. It may also be the one that will ensure you have the most consistent ingredients in your capsules.

The first step in the process is to remove the body and caps of the capsules. The machine then assembles the body and caps together in a sandwich-like manner. These two parts are then placed underneath a powder hopper. The powder is then evenly pushed down into the capsules using a corkscrew.

Capsules are then moved in a circular motion. The corkscrew will ensure that all capsules are of similar weight. Then, they are sealed. The machine will automatically turn off if there is an error. During this process, the machine is likely to produce a capsule that is the best of the best.

The user interface of the machine will also be an important factor. A machine that has an automated loading station will reduce operator fatigue and help you achieve higher production speeds. In addition, a machine that is able to change settings as needed will give you the flexibility you need to produce accurate weights.